Lessons learnt from 3D printing in the world’s largest Syrian refugee camp

Timely access to tools that are responsive to field needs is critical in the delivery of humanitarian interventions. Unfortunately, humanitarian procurement processes and supply chains are often rife with queued requisitions, complex hierarchical approvals, and inflexibility, creating challenges to accommodating urgent or specialised needs (e.g. replacement of a worn-out/broken equipment part). It is estimated that 60–80% of humanitarian aid money is spent on procurement, therefore strategic efforts to minimise transportation and [re-]ordering of needed items can have a significant effect on costs, programme implementation, and impact delivery.

The emergence of small-scale local manufacturing using 3D printing technology has created field-based opportunities for on-demand and real-time production of tools and objects. Appropriate implementation of the technology shows promise for humanitarian contexts where urgent needs for hardware are common. Yet, reliance on technology to fill gaps in humanitarian interventions must be guided by careful matching with contextual realities through validation trials (or testing) under field conditions. Although 3D printers have been used in various contexts, limited empirical evidence exists to demonstrate the potential of the technology in a humanitarian context.

Taking 3D printing to the field

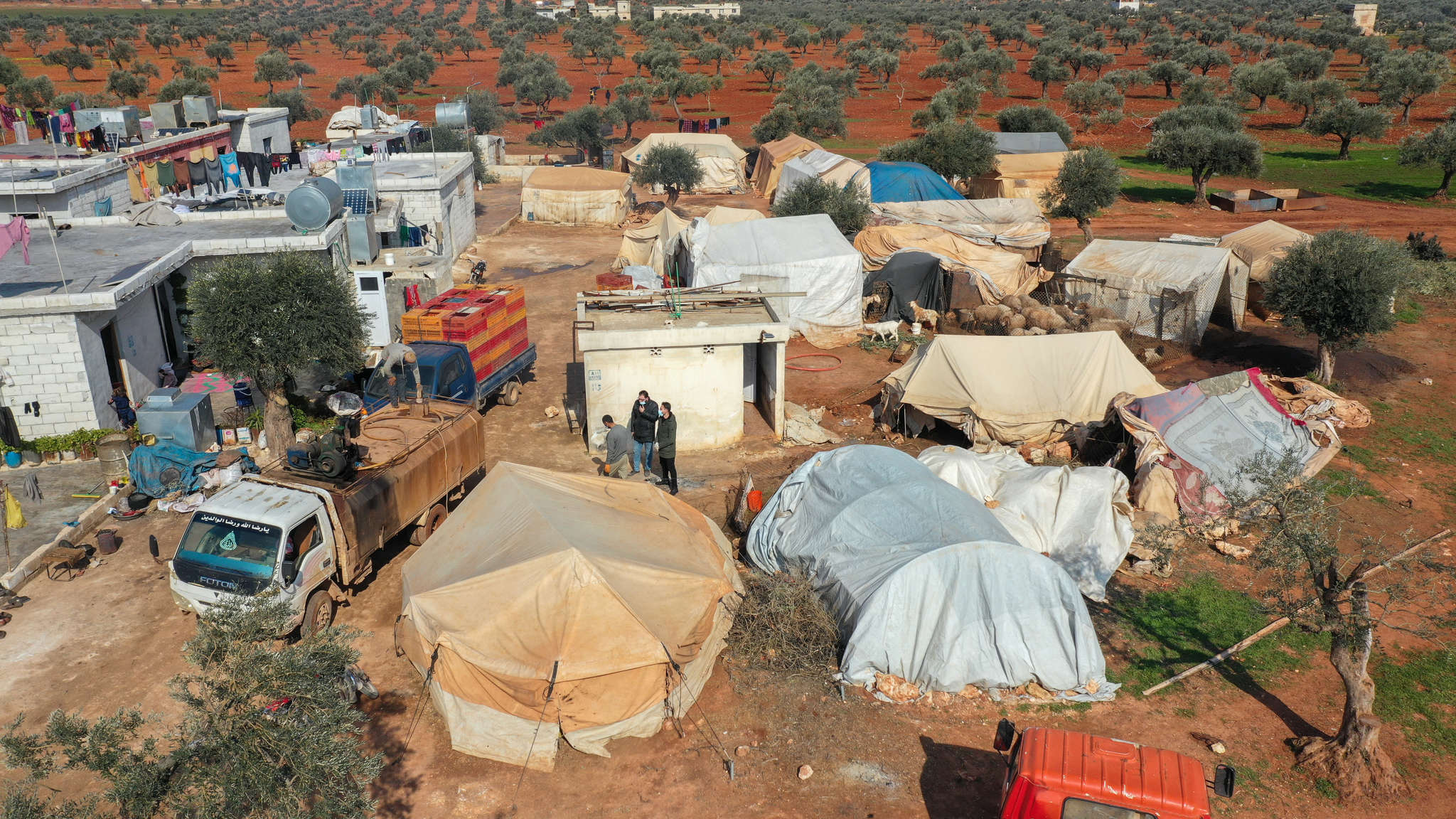

In the autumn of 2018, Mercy Corps’ field team in Jordan undertook a bold initiative to test the use of 3D printing at the Zaatari Refugee Camp, located about 70km outside of Amman, Jordan. The camp hosts about 80,000 Syrian refugees, many of whom have been living in the camp since 2012, and operates like a “functioning city”, with provision of basic social amenities including schools and community-based centres (including a centre operated by Mercy Corps’ and known as “Dreamland”). Within the camp, various needs exist for procurement of adaptive or assistive hardware objects to support day-to-day operation or participant needs.

There is a large number of children among the camp’s population, many with physical or developmental challenges and who are in need of assistive equipment in order to participate fully in educational and recreation activities. In the past, the needs were catered for on an ad hoc basis, with one of the most noteworthy successes being a craftsman programme run by Mercy Corps at the Dreamland centre. In that programme, skilled craftsmen, who were themselves residents of the camp, were given access to training, equipment, and materials and a place where they could hand fabricate accessibility aids for the children in the camp.

The 3D printing field test focused on 2 aspects: Procurement and installation of the 3D printer, and capacity development of the volunteer craftsmen. The goal of the programme was to train the craftsmen on how to use the 3D printer to fabricate accessibility aids, and in the process, they would learn how to engage with this technology in field environments.

The process — Navigating the unknowns

The ability of field teams to adopt and sustain specific technologies (and tools) is often dependent on their skill level and their confidence in the use of the tool. The critical components for implementing 3D printing include the software, the hardware, and human competence. Optimising these components relative to desired objectives involves nuanced understanding of the technical and non-technical aspects. Moreover, as the use of 3D printing was a new concept inside Zaatari camp, there were initial unknowns related to acceptability, environment, and priority needs of programme participants/beneficiaries.

Prior to the launch of the pilot, initial scoping was conducted to assess the opportunity and demand for 3D printing within the Camp. For instance, the decisions relating to the selection of hardware, input materials, and vendors were guided by various considerations, including need, local availability, suitability for the proposed objects, and ease of procuring spare parts/accessories. Also, consultations were made with the management of the refugee camp because they play a key role in housing and securing the hardware and accessories. Discussions with Mercy Corps’ occupational therapists and special education experts proved beneficial to ensure that printed objects were vetted to meet required specifications, without posing any potential risk to users and to the camp’s operations. Initial evaluations of the power supply requirements, computer specifications, space availability, and programme schedule were also made to ensure that the field trial activities and hardware could be accommodated within the limits of available resources.

The design and 3D printing of objects is, generally speaking, a repetitive process starting with modeling/design of each object, then building of the element(s), followed by post-processing. To accelerate the programme, Mercy Corps contracted a third party provider who installed the printer and did the initial device set-up, in conjunction with members of the workshop. Initial efforts with the printer started with designing and printing basic objects (such as small figures like finger splints and eyeglass frames). The initial demo/test-runs with these basic objects allowed the trainees to evolve progressively in their understanding of the principles and processes of 3D printing as a precursor to the printing of more complex objects (including adaptive tools, insoles, and protective hands). As complexity increased, more time was spent in iterations of the printing process and in pre-production tests of various designs.

The challenges

During the field trial, the major issues encountered related to technical capacity and external environmental factors. On the technical side, only one 3D printer (and later, a 3D scanner) was procured and available to the team, so this limits the duration for each trainee to acquire hands-on experience with the equipment and process. Similarly, although the team considered the possibility of extending this initiative to nearby camps where 3D printing of assistive tools/objects was also in demand, the stationary set-up of the hardware precluded this interest. The limitations were addressed by scheduling group-based hands-on design and printing sessions for the pool of trainees, while the interest to go beyond Zaatari camp was eventually set-aside until resources became available to procure more hardware.

While printing of simpler objects was duly mastered, the design and printing of larger assistive tools, such as prosthetic hands, was non-trivial for the volunteer trainees. To ensure that the nuances of the complex elements (joints, symmetry, flexibility etc) are duly factored into the final output, multiple consultations were made with the target user and medical experts, and multiple iterations were required to test different materials and designs.

The environment of the camp also presented challenges. The 3D printer requires continuous power supply and the design utility software requires an internet connection, however, neither of these were constantly available in the camp. On many occasions, ongoing printing tasks are truncated (sometimes after several hours run) due to power or internet outage, especially during periods when the alternative power source (such as electric power generators) is working at reduced capacity due to demand for other purposes. Interruptions often resulted in lost jobs and the necessity to restart the printing process from the beginning, causing lost time and materials. Camp regulations prevented the installation of uninterruptible power supplies (UPS); under other conditions, at least, the presence of a UPS would have saved some of the jobs.

The outcomes of the field testing

The use of 3D printing technology is still evolving and has a promising outlook. There are practical considerations that should guide application in humanitarian settings, such as availability of background technical expertise, sourcing of input materials, technical training, equipment maintenance and repair, reliable power, reliable internet, and security for hardware and safety. Although 3D-printing can support strategic efforts to minimise (or obliterate) the limitations of procurement and access to adaptive tools, the field piloting of the technology highlights a reality check on several topics, including:

- scaling and the limitations of bespoke manufacturing

- the need for more research and expert support (mainly for iterating and printing complex items, such as prosthetics)

- limitations on the capacity of machines translates into limits on the size of objects that can be printed in a single job

- non-availability of steady internet and electric power access

- different printing materials are needed for different types of jobs (PLA filament was used in this trial)

- building team design capacity can be challenging

At the conclusion of this trial, Mercy Corps opines that 3D printing is valuable for meeting specialised needs under varying contexts, despite the challenges and constraints encountered. Arguably, the core value proposition for its use in humanitarian context is that field teams can be empowered to respond to emergency procurement needs for tools or assistive objects, allowing them to escape at least some of the challenges that accrue to supply chains in times of crisis. As the technology gains traction and becomes more embedded in humanitarian programmes, improved production efficiency may be achieved with repetitive printing of large quantities of a single item (i.e. batch printing) and easy/open-access to optimised 3D design templates and guidelines. Looking forward, Mercy Corps will continue to explore ways to expand 3D printing activities in various locations and in response to a wider variety of use cases.

The Technology for Development (T4D) team is conducting these pilots through generous partnership with Cisco, under a 5-year programme aimed at using technology to deliver aid and development assistance faster, better, and to more people.